Sustainable Strategies for Precious Metal Recovery

More than $60 billion in precious metals end up in e-waste every year—did you realize that? That eye-opening statistic shows how important recycling these metals really is. Not only does it boost economic health, it also protects our environment. Reclaiming gold, silver, platinum, and palladium helps lower pollution and preserve what’s left of our natural resources.

Firms like Dongsheng Metal Trading spearhead the movement toward greener recycling. They make sure those precious metals get reused rather than landfilled. This precious metals recycling companies approach is key to eco-friendly recycling and sustainable practices.

Core Insights

- Each year, e-waste discards over $60 billion in precious metals.

- Precious metal recycling reduces environmental impact and conserves resources.

- Key precious metals are gold, silver, platinum, and palladium.

- Eco-friendly recycling practices are vital for sustainable development.

- Recycling experts like Dongsheng Metal Trading lead the industry.

Understanding Precious Metals and Their Value

Naturally scarce metallic elements called precious metals draw interest from industries and investors. Gold, silver, platinum, and palladium stand out for their distinct qualities. These include electrical conductivity, corrosion resistance, and substantial rarity. Extracting and refining them uses up huge resources, so recycling becomes critical.

Intrinsic qualities and demand in the marketplace determine precious metals’ worth. Recycling precious metals plays a critical role in sustaining the supply chain. It cuts the environmental toll of mining operations. Advanced recycling can bring metals back to their initial quality. Such efforts save limited resources and create economic gains.

Defining Precious Metals

Unique features make precious metals ideal for many uses. Their rarity and intrinsic properties are foundational to their economic significance. Notable examples are:

- Gold: Valued for its beauty and resistance to tarnish.

- Ag: Celebrated for its adaptability and conductivity.

- Pt: Renowned for strength and catalytic uses.

- Pd: Gaining traction in cars and electronics.

Benefits of Precious Metal Recycling

The practice of recycling precious metals has emerged as a vital component for sustainability. It preserves resources and lessens the environmental cost of mining. Key benefits include:

- Lessening of habitat destruction from mining.

- Lower energy consumption compared to extracting new metals from the earth.

- Supporting a circular economy via material reuse.

- Potential for financial gains through the reclaiming of high-value materials.

The Importance of Precious Metal Recycling

Metal recycling brings both green and economic gains. Highlighting these advantages is key to reducing our ecological footprint. It also drives economic growth and stability.

Eco Advantages

The environmental benefits of recycling precious metals are significant. When we recover metals from e-waste and scrap, landfill volume drops. This reduces the need for new mining, conserving natural resources.

It lessens mining impacts, including ecosystem harm and contaminants. By prioritizing recycling, we work toward a greener tomorrow.

Financial Gains

Economic upsides of recycling stand out equally. Recovering metals cuts production expenses. This allows industries to use reclaimed metals instead of new ones.

This shift creates jobs in recycling facilities and boosts market stability as demand for recycled metals grows. Using these financial benefits, companies can improve profits. They also contribute to a greener economy.

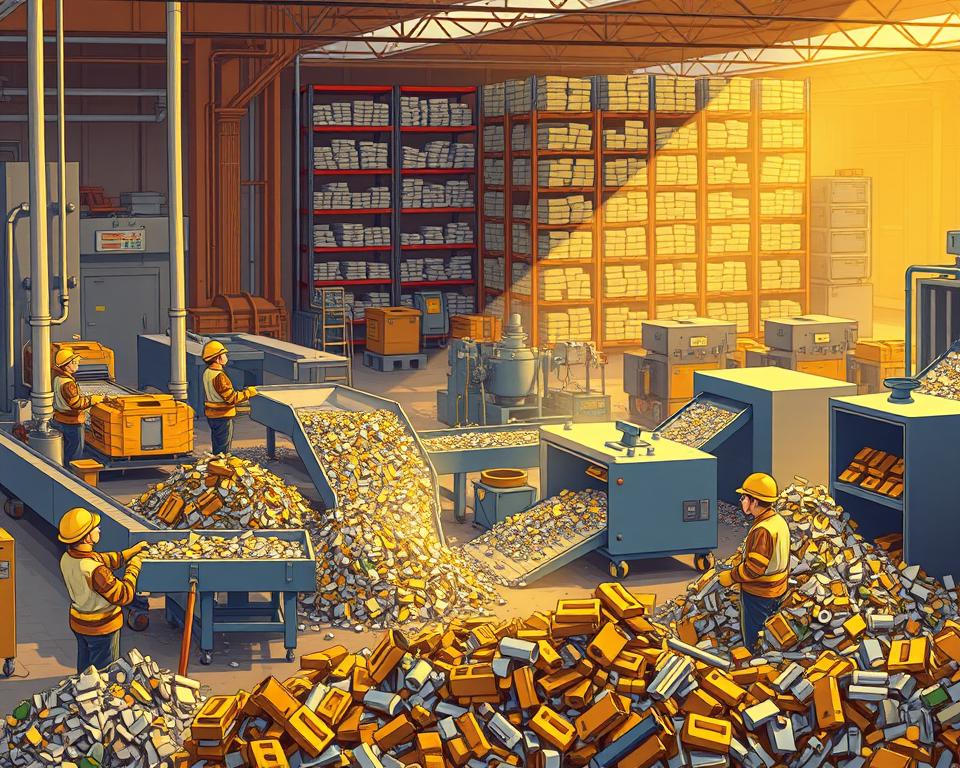

How Precious Metals are Recycled

The precious metal recycling process is complex, involving several stages to ensure maximum efficiency. Collection of e-waste, jewelry, and industrial scrap kicks off the process. These materials then undergo sorting, cleaning, and analysis to determine their composition and value.

Recovery Steps

A structured workflow is key to high-yield recovery. All stages focus on boosting metal yield. Sorting separates metals by type and purity. Decontamination eliminates residues that block recovery. Analysis identifies the concentration of precious metals, guiding the choice of recycling techniques.

Recovery Methods

High-tech methods are used to maximize metal retrieval. One method, thermal reduction, leverages heat to separate metals from base materials. Smelting and chemical baths extract and purify metals. Recyclers like Dongsheng Metal Trading employ these approaches to improve yields and returns.

Which Precious Metals Are Recyclable

Recycling is vital for the environment and for recovering valuable materials. A host of precious metals are recyclable, aiding markets and ecosystems. Awareness of recyclable metals guides consumers and companies.

Gold, Silver, and Platinum

Gold, silver, and platinum stand out among precious metals. They appear in jewelry, coinage, and industrial components. Gold’s high price and use make it a prime recycling target. Silver recovery matters too, thanks to its role in imaging, tech, and solar.

Platinum, though less common, is valuable, mainly in catalytic converters.

Electronics Precious Metals

E-waste metals present special recovery opportunities. Smartphones, laptops, and tablets contain rare metals like palladium and indium. Reclaiming them cuts e-waste and recovers key resources.

The need to recycle these metals is critical. Businesses work to reduce scrap and upscale resource recovery.

Industries that Benefit from Precious Metal Recycling

Precious metal recycling is essential for several key industries, allowing them to use valuable resources efficiently and sustainably. The electronics industry, with its frequent use of precious metals in devices, benefits greatly. Aerospace and medical sectors also depend on these metals for critical components. Exploring how these industries recycle precious metals reveals the environmental and economic benefits.

Tech Electronics

Electronics spearheads recovery, given the metal content in phones and PCs. Quick device turnover spawns more electronic scrap. This makes effective recycling of these metals, such as gold, silver, and palladium, critical. That saves resources and cuts mining carbon footprints.

Companies are increasingly focusing on recycling to meet global sustainability and waste reduction goals. Such a move upholds efforts to conserve and protect.

High-Tech Industries

Metal recovery is key in aerospace and medical sectors where metals are in vital parts. High-performance alloys are essential for manufacturing flight parts and medical devices due to their durability and resistance to corrosion. Recovering them cuts costs and meets green regulations.

They recognize that recycling offsets material scarcity. And it improves operations, making metal recycling a smart green tactic.

Finding Precious Metal Recycling Companies

Choosing reputable metal recyclers is vital for success. It’s wise to ask important questions to understand their operations. Pricing models and processes make a big difference. By comparing services, you can see what each company offers and make a smart choice.

Questions to Ask Recycling Companies

- Which recovery certifications does your company have?

- What techniques do you use for each metal type?

- What are your recovery rates for various precious metals?

- How do you handle pricing, and what additional fees might apply?

- Can you provide references or testimonials from previous clients?

Comparing Prices and Services

You must evaluate services side-by-side to pick the right recycler. Use a table to line up these factors:

| Company Name | Recovery Rate (%) | Processing Fee ($) | Turnaround Time (Days) |

|---|---|---|---|

| Recycling Co. A | 95 | 50 | 7 |

| Recycling Co. B | 90 | 45 | 5 |

| Recycling Co. C | 92 | 55 | 10 |

By comparing recycling services, you can find the best recycler for your needs. It guarantees maximum value and compliance.

Recycling Precious Metals: A Green Guide

Understanding how recyclers operate is key for those interested in precious metal recycling. They oversee everything from scrap pickup to refining. That approach drives top efficiency and returns.

How Recyclers Operate

Recyclers use advanced methods for metal recycling, including testing, separation, and refining. Collection comes from devices, jewelry, and industrial waste. Afterwards, they apply refined techniques to isolate each metal. In the last stage, precious metals are refined to purity.

This process not only maximizes resource recovery but also supports eco-friendly practices. It’s fundamental to building a sustainable future.

Selecting Your Ideal Recycler

Key criteria matter when choosing a recycler. Begin by checking their green credentials. In today’s market, a commitment to sustainability is essential. Also, consider the services they offer, from basic collection to full processing.

Pricing is another key factor. Request estimates from multiple firms. Experts like Dongsheng Metal Trading provide industry-specific offerings. They are a reliable choice for specific recycling needs.

The Role of Metal Recycling Facilities

Metal recycling is a critical sector for sustainable practices and waste management. There are specialized centers for different metals and materials. Awareness of facility types guides you to proper recyclers. This benefits both businesses and the environment.

Recycling Center Types

Metal recycling facilities vary widely in their operations. Some yards recover gold and silver; others accept all metal waste. Here are a few common types:

- General scrap yards handle both ferrous and non-ferrous materials.

- High-value metal recyclers provide precision recovery for gold, silver, platinum, etc.

- Electronics recyclers extract metals from old gadgets.

Location and Access to Facilities

Proximity to recyclers cuts logistical hurdles. Firms need to plan transport logistics. Here are some factors that influence access:

| Factor | Description |

|---|---|

| Distance | Facilities located nearer to businesses minimize transportation costs and time. |

| Networking | Strong ties with local centers streamline recovery. |

| Service Range | Understanding the specific services of metal recycling facilities helps businesses select appropriate partners. |

Choosing appropriate centers and easy access drives recovery efficiency.

Recovering Metals from E-Waste

E-waste poses a major ecological challenge. Many e-waste items hold recoverable precious metals. This highlights the importance of seeing e-waste as a valuable resource.

How Electronics Contain Precious Metals

Gadgets harbor small quantities of precious metals. You’ll find them in components such as:

- Circuit boards

- Connectors and ports

- Capacitors and resistors

- Battery terminals

From phones to TVs, electronics pack precious metals. Recycling lets us reclaim and repurpose those metals.

The Importance of E-Waste Recycling

Recovering e-waste metals safeguards the environment and reclaims materials. It trims dump loads and conserves raw materials. The benefits of recycling e-waste metals are clear:

- It minimizes environmental risks from improper disposal

- It reduces CO₂ output via green recycling methods

- It bolsters circular models by returning scrap to production

Championing electronics recycling fosters responsible resource use. It’s essential for the well-being of future generations.

What’s Next in Metal Recycling?

Metal recycling is evolving, spurred by tech advances and green initiatives. With resource conservation rising, recyclers are innovating. Adopting fresh techniques, they’re shaping tomorrow’s recycling.

Trends in Sustainable Recycling

Current trends in sustainable recycling focus on reducing waste and minimizing environmental impact. Businesses adopt green packaging and energy-saving techniques. That evolution supports global green targets and fosters industry responsibility.

Cutting-Edge Recovery Methods

Advances in recovery techniques are key to improving precious metal recycling efficiency. New technologies, such as automated sorting and hydrometallurgical extraction, enhance recovery rates. They ramp up yields and shrink eco-footprints, advancing metal recycling.

Launching a Metal Recycling Startup

Building a metal recycling enterprise calls for thorough planning and industry knowledge. Leaders should map out steps, secure compliance, and set firm roots. This includes conducting extensive market research and identifying target clients. Permits and regulatory clarity underpin ongoing success.

Launching Steps

To launch your recycling venture, follow these steps:

- Analyze market demand and competitor landscape.

- Create a comprehensive plan with objectives and tactics.

- Purchase the right gear for your recycling operations.

- Secure funding through loans or investments.

- Secure regulatory approvals and certifications.

- Implement a marketing strategy to draw in customers.

Compliance and Certifications

Understanding legal aspects when starting a precious metal recycling business is critical. Complying with eco-regulations keeps your business green and lawful. Must-know compliance points:

- Securing business certification from relevant authorities.

- Ensuring full compliance with disposal and recycling laws.

- Training staff in safety protocols and best practices.

The Final Word

Recovering precious metals conserves resources and protects our planet. It allows individuals and businesses to lessen waste’s impact on our planet. That reclaimed metal cuts mining demand and spawns recycling jobs.

Beyond green gains, recycling yields financial perks. Teaming with Dongsheng Metal Trading secures sustainable methods. This collaboration strengthens the circular economy, benefiting both recyclers and consumers.

The journey to a sustainable future depends on collective action in recycling precious metals. Raising awareness fosters mindful use and eco stewardship. Adopting these practices will benefit us now and secure a greener future for generations to come.